Big news is quietly circulating through the world of real cinema, the cimema with motion picture film: Kodak is preparing to eliminate the remjet layer from its VISION3 film stocks. For many, this might sound like an obscure technical footnote. But for those of us who process film independently, it marks a turning point.

The remjet layer has historically been an integral component in professional color negative motion picture films. It served a variety of purposes: anti-halation to prevent light from reflecting back through the base and fogging the image, anti-static to reduce dust, a lubricant for high-speed transport in cameras and projectors, and a protective shield against scratching. In short: essential for industrial usage.

|

| Catalogue code for AHU stock starts with numbers 751 |

But in the world of Super-8, some of these benefits are less relevant. Super-8 cartridges run at standard speeds, are less prone to static build-up, and don’t face the same mechanical stresses as 16mm or 35mm. Yet, until now, the remjet remained standard on all professional motion picture stocks, including those reperforated for Super-8.

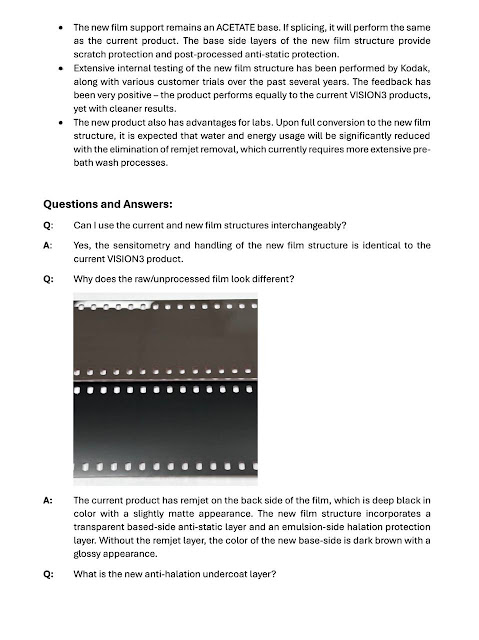

For independent filmmakers, like myself and others who process Super-8 or 16mm at home or in small labs, removing the remjet has always been one of the most challenging steps. It involves pre-baths or post-baths, a separate chemical stage, even mechanically, and a great deal of care. With expired film stocks, remjet removal often becomes unpredictable and can leave residue or stains.

Now, Kodak has quietly confirmed this change: future VISION3 stocks will be manufactured without the remjet layer, with a new procedure called AHU (acronym of anti-h alation undercoat).

|

| AHU code is 751 but art of the box is the same |

Removing remjet took years of internal research. Kodak has invested millions of dollars in this development, which required the closure of the production plant for a few weeks at the end of 2024 to adapt to the new technology. Kodak had to redesign the base to include anti-halation properties below the emulsion layers, without changing the film’s total thickness. That meant re-engineering all the emulsion layers to be slightly thinner. As a result, the silver-bearing layers had to be recalibrated to maintain consistent density. Otherwise, development would be off, leading to overexposure or unwanted color shifts.

The traditional carbon black remjet layer has been replaced with a newly engineered process-surviving anti-static layer. This innovative solution not only provides the essential functions of the original remjet—such as lubrication, scratch resistance, and spark protection during camera transport—but also introduces a valuable enhancement: it remains active even after development.

This means the film retains its anti-static properties post-processing, offering increased resistance to airborne particles that typically cling to film surfaces. The practical result? Expect noticeably cleaner digital scans, with fewer dust artifacts and improved image fidelity—especially important for those working with high-resolution transfers.

This is no small feat. Motion picture films are chemically complex ecosystems. Any tiny change requires rebalancing the entire development process.

Should Kodak naming this new formulation "VISION4? Kodak chose not to rename the new stock "Vision4" because, historically, changes in the Vision platform—such as the transitions from Vision to Vision2, and then to Vision3—have been tied to significant advancements in imaging science. The recent modification, introducing the AHU (anti-halation undercoat), is a structural adjustment rather than a change to the image-forming emulsion itself. Since the core visual characteristics of the film remain the same, Kodak decided to retain the Vision3 branding. Perhaps, the new film could be called Vision 3- II, as happened in 1961 with improved Kodachrome II.

|

| A recreation of what the new cartridge could have been. |

A NOTE ON IDENTIFICATION AND PROCESSING CONCERNS.

The catalog code assigned to the AHU Vision film in Super 8 format is 751. This identifier appears only on the bulk packaging for 20-cartridge shipments to retailers, but not on the individual boxes received by filmmakers. This discrepancy may lead to confusion in the future, especially when differentiating between the older remjet-backed VISION3 and the newer AHU-based stock.

It's worth nothing that professional labs are expected, eventually, to discontinue processing films with remjet backing, as they will begin bypassing the remjet removal stage entirely—eliminating the scrubber box from their ECN-2 workflow. This will result in considerable water savings and reduced maintenance, but it also means that understanding emulsion codes and manufacturing distinctions will become increasingly important. For those with older remjet-backed stocks still in their refrigerators, the message is clear: shoot them sooner rather than later, or be prepared to pay a premium for processing, as labs may charge extra to temporarily re-enable the remjet removal setup.

ADVENTAGES OF NEW TECHNOLOGIE AHU.

This new technologie means the film retains its anti-static properties post-processing, offering increased resistance to airborne particles that typically cling to film surfaces. The practical result? Expect noticeably cleaner scans, with fewer dust artifacts and improved image fidelity—especially important for those working with high-resolution transfers.What does this mean for us, the independent Super-8mm filmmakers?

Simpler processing: Without remjet, home processors and boutique labs can simplify their workflows.

No more remjet removal failures: Especially when dealing with expired film, so:

Noticeably cleaner digital scans, with fewer dust artifacts and improved image fidelity, very important for Super-8 filmmakers working with high-resolution transfers.

Is Kodak moving toward ending other film lines, like photographitc C-41 emulsions? I don´t think so. Despite rumors, there are no current plans to discontinue existing photographic stocks. Far from disappearing stocks, it seems there will be more as there are plans to launch at least one stock of the Portra range in 35mm motion film presentations. The internet may be noisy, but real news travels through quieter channels.

In conclusion: for us in the trenches of filmmaking, this change is significant. One less obstacle in development. One more sign that cinema is evolving to adapt, survive, and even thrive in unexpected ways.

We Super-8 filmmakers don't just create movies: we celebrate shooting with film, frame by frame. And if the emulsion gods smile upon us, perhaps this is just the beginning.

Stay tuned for upcoming tests with the new remjet-free materials as they begin to hit the market.

Long life to motion picture film! Thanks Kodak.

Post scriptum: 3 months after the blog post, American Cinematographer published a very interesting article about this subjet: PLEASE, READ HERE

ADDENDUM: Days after the blog post, Kodak published the following information.

No hay comentarios:

Publicar un comentario